Core Facility

Microfabrication Core

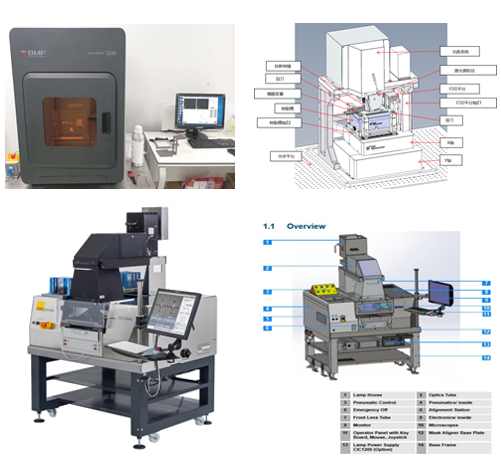

The Microfabrication Core is dedicated to applied research and technological development of precision manufacturing technologies in the biomedical field, providing efficient and accurate technical support for scientific innovation and industrial transformation. Equipped with a Class 1000 yellow-light cleanroom, the core features a complete microchip preparation and characterization process system. Key equipment includes a mask aligner, a lithography fume hood, spin coaters, a plasma cleaner, a metallographic microscope, and a profilometer, enabling full-process technical services from chip design to performance validation.

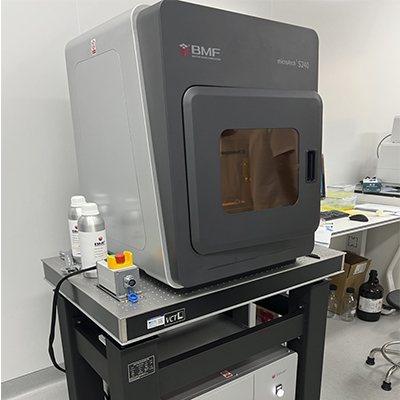

The core also houses advanced instruments such as a high-precision stereolithography 3D printer, a rapid-prototyping FDM 3D printer, and a hot-embossing machine, expanding material and process options for fabricating biochips, micro biochemical reactors, and prototype models with micron-level precision to meet diverse needs of basic research and product development.

Bioprinting services are being expanded, covering extrusion-based and stereolithography-based bioprinting technologies.

To facilitate chip-related research, the core offers not only conventional chip fabrication and characterization services but also experimental guidance, laboratory space, and equipment for chip application studies, including micro-injection pumps, valve control systems, a stereoscopic fluorescence microscope, and an inverted fluorescence microscope.

As a key component of the Equipment R&D Center within the integrated Shenzhen Bay Laboratory - Shenzhen Academy of Medical Sciences, the Microfabrication Core collaborates with affiliated platforms to provide precision engineering solutions (CNC machining, precision welding, laser cutting) and customized experimental equipment R&D.

Contact

Contact:Xiaohu Zhou

Email:zhouxh@szbl.ac.cn

Email:zhouxh@szbl.ac.cn